We supply inspection testing equipment for testing the following surface properties:

- Surface cleanliness – mill scale on a steel substrate can lead to accelerated corrosion. To determine if there is any present, spray a fine mist of copper sulphate solution onto the area. The steel will turn a bright copper colour and any mill scale particles will show as black spots.

- Surface profile – a surface profile needle gauge measures and records peak to valley surface profile heights. The needle reaches the bottom of the troughs on the surface profile. Several readings are usually recommended with this method, and an average is taken.

- Environment conditions – it is essential when applying a coating to measure and record the climate conditions. This will indicate whether it is permissible to apply coatings in these conditions. Relative humidity and dew point are particularly important.

- Salt contamination – colourless soluble salts may be present in pits within the substrate after blast cleaning, which can accelerate corrosion. Using the bresle patch testing method in accordance with ISO 8502-6 and ISO 8502-9, the concentration of soluble salts can be measured and recorded.

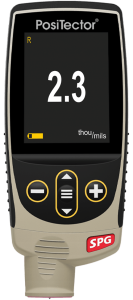

- Coating thickness – dry film thickness is the single most important measurement made during the application and inspection of protective coatings. This type of gauge is the economical test method for measuring dry coating thickness on metal substrates.

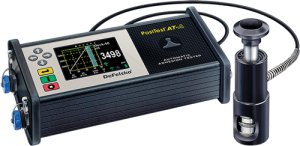

- Coating thickness – all metals. The comprehensive coating thickness probe for all metal substrates is a rugged fully electronic coating thickness probe that uses magnetic and eddy current principles to measure coating thickness. It works on both ferrous and non-ferrous metals, accurately and quickly.

- Coating thickness – non-metals. Non destructively measures a wide variety of applications using ultrasound technology.

- Pinhole/porosity – an operation to detect any holes/holidays in a coating or wrapping. Inclusions in coating often lead to coating failures and can accelerate corrosion.

- Ultrasonic wall thickness – measures the wall thickness of a range of different materials to help determine the physical state of the substrate without having to remove the coating first. Determines whether the wall is deteriorating, corroding away, simply and effectively.

- Adhesion – failure in adhesion often occurs between the uncoated substrate and the primer, due to inadequate wetting of the substrate. This may be because of insufficient surface preparation, insufficient dust removal after surface preparation, or contamination.