Hodge Clemco have recently supplied a turnkey blast cabinet solution for a company who contacted us to look at ways of helping them with their production performance. The company are a leading supplier to the energy industry of tubes and other related services.

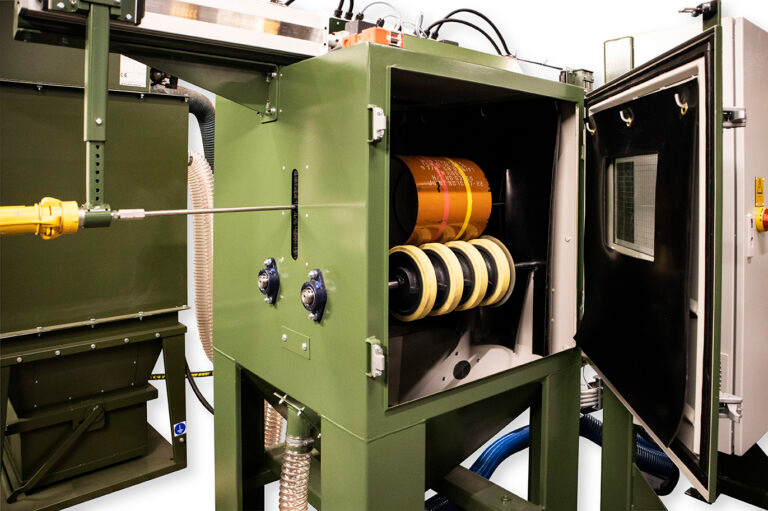

Our Area Sales Manager had various meetings online and onsite with the company to work on a solution. The process developed into to an automated set up for a blast cabinet to allow an efficient blast profile on the company’s products. But also deal with production issues. This set up would save time on jobs but also free up manpower. After some design changes, we investigated the parts being loaded onto rollers to allow the parts to be turned easily. Further, allowing the blasting process of the components ID to be easier to distinguish.

Having inverters fitted within the cabinet allowed rotational speed and nozzle positioning. A control panel to program was also fitted and set up for various size of job within the chamber of the blast cabinet. This proved to be a valuable asset, not only to the job but to the company.

Our team of experts here at Hodge Clemco were able to design and manufacture a special pressure blast cabinet to suit the customers’ needs. Capable of accommodating and processing specific parts within its fully illuminated work chamber. As per the requirements.

- Inverters to provide rotation & nozzle speed control.

- Control panel with settings for the roller speed, reciprocator speed and number of reciprocations.

- Twin outlet pressure blast machine with independent nozzle switching, pressure regulator and blow down feature.

- Upgraded dust extraction system with high pressure fan for efficient media recovery.

The finished cabinet will allow the companies parts were to be loaded into the cabinet via the central door of the blasting enclosure and lowered onto the rotation rollers. This is an efficient and safe way of loading the machine. Along with safety being at its highest importance with door interlocks in place, when the machine is in motion and cycling. When the cycle is complete, all the door interlocks will release to allow the component to be unloaded safely.