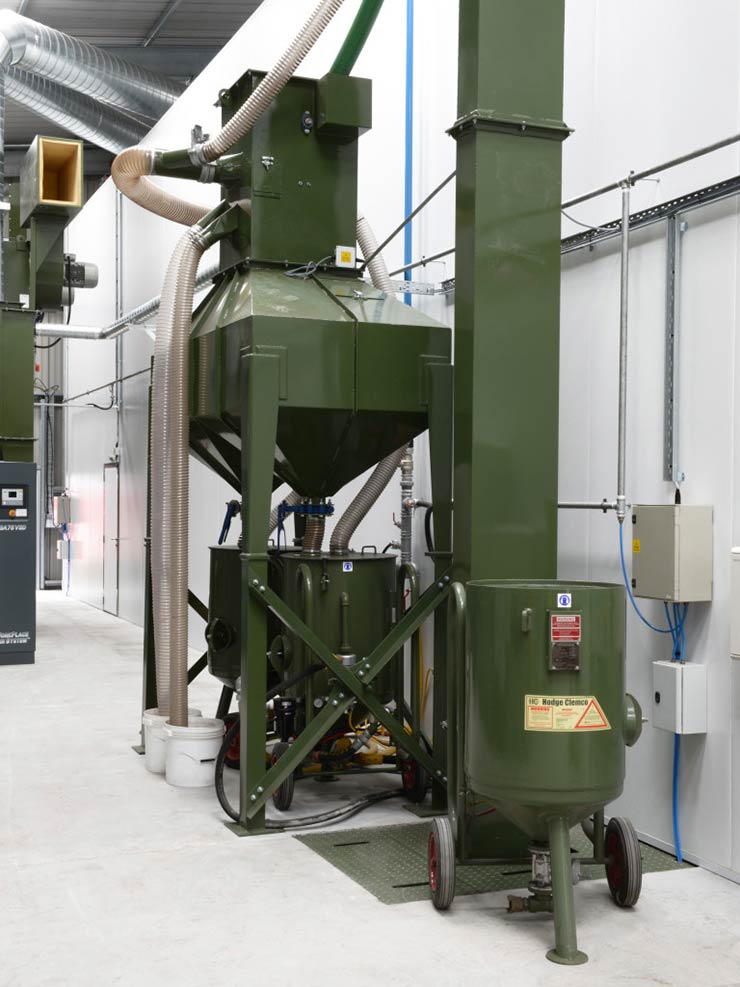

Hodge Clemco’s Belt and Bucket Elevator System is a heavy duty grit recycling unit, coupled to an abrasive separator which is designed to continuously remove large amounts of contamination. The heavy-duty nature of this system enables multiple operators to run from one unit. The system can be operated with a simple sweep in floor hopper or to increase production, can be coupled to an under-floor scraper or screw system. The modular nature of the design enables the system to fit in most site conditions and requires minimal foundation work.

Hodge Clemco’s Belt and Bucket Elevator system is a tried and tested design and is specifically suited for high production applications. The Bucket Elevator recovers the abrasive from a metering chute fed from a gravity hopper, scraper floor or screw conveyor. The abrasive and contamination is lifted by buckets mounted onto the elevator belt. The media is discharged into the scalping drum inside the abrasive separator, which removes oversize contamination automatically. The dust is removed from the reusable abrasive via an air wash from the dust collector. The cleaned material then gravitates through to a silo mounted above the blast machine(s). The capacity of the silo and the quantity of outlets are selected to suit the application.

Blast Room and Abrasive Recovery System Owner’s Manual (252F pt.1)

Abrasive Recovery System Owner’s Manual (252F pt.2)